Electrical codes represent decades of accumulated knowledge about what keeps electrical systems safe and functional. These detailed regulations cover everything from wire sizing and circuit protection to installation methods and safety devices. While they might seem like bureaucratic obstacles to homeowners eager to complete projects quickly and inexpensively, electrical codes serve a critical purpose: preventing fires, electrocutions, and equipment damage.

Understanding why electrical codes exist and what they accomplish helps explain why professional installation from licensed electricians isn’t just recommended—it’s essential for safety and code compliance.

The Foundation: The National Electrical Code

The National Electrical Code (NEC), also known as NFPA 70, provides the foundation for electrical safety standards throughout the United States. Published by the National Fire Protection Association and updated every three years, the NEC reflects current best practices for electrical installation based on extensive research, field experience, and evolving technology.

According to the National Fire Protection Association, the NEC aims to protect people and property from electrical hazards through practical safeguarding requirements covering electrical installations. The code addresses conductor sizing, protection methods, installation practices, and special equipment requirements across hundreds of pages of detailed specifications.

States and local jurisdictions adopt the NEC as their electrical code, sometimes with amendments reflecting regional considerations. Virginia adopts recent NEC editions with state-specific modifications addressing local conditions and priorities. Northern Virginia jurisdictions may add additional requirements beyond state minimums, creating a layered regulatory framework.

The NEC updates every three years to address emerging technologies, new hazards, and lessons learned from electrical failures. What was compliant ten years ago might not meet current standards. This constant evolution explains why experienced electricians invest in ongoing education—staying current with code changes is essential for safe, compliant work.

Wire Sizing and Circuit Protection

One of the most fundamental code requirements involves matching wire size to circuit load and providing appropriate overcurrent protection. Using undersized wire for a given load creates serious fire hazards as current flow generates heat beyond the wire’s capacity.

The NEC specifies minimum wire gauges for different amperage loads. A 15-amp circuit requires minimum 14-gauge wire, while 20-amp circuits need 12-gauge wire. Higher amperage circuits demand progressively heavier wire—10-gauge for 30 amps, 8-gauge for 40 amps, and so on.

But proper sizing involves more than just matching wire gauge to breaker size. Code also accounts for wire run length, ambient temperature, conduit fill, and installation methods—all factors affecting wire capacity. Long wire runs require heavier gauges to prevent voltage drop. Wire in hot attics or bundled with other conductors can’t carry as much current as wire in ideal conditions.

Circuit breakers must match both wire capacity and expected loads. A 20-amp breaker on 12-gauge wire protects the wire from overcurrent damage. But if the circuit serves outlets where high-draw devices might be plugged in, code requires careful load calculation ensuring total connected devices won’t exceed circuit capacity.

Professional electricians understand these complex relationships and apply code requirements appropriately for specific situations. DIY installers often miss critical factors leading to code violations and safety hazards.

Ground Fault and Arc Fault Protection

Modern electrical codes require sophisticated protection devices that detect hazardous conditions and disconnect power before fires or electrocutions occur. Ground Fault Circuit Interrupter (GFCI) protection prevents electrocution in areas where electricity might contact water. Arc Fault Circuit Interrupter (AFCI) protection guards against electrical arcing that can ignite fires.

GFCI protection became required for outdoor outlets in the 1970s, then expanded to bathrooms, garages, crawl spaces, and eventually all kitchen countertop outlets. Current code requires GFCI protection for virtually any outlet where water contact is possible. This includes bathrooms, kitchens, garages, basements, crawl spaces, outdoor areas, and laundry rooms.

AFCI requirements emerged more recently in response to research showing electrical arcing causes significant fire losses. Modern code requires AFCI protection for most residential circuits. The exact requirements vary based on which NEC edition your jurisdiction has adopted, but trend toward comprehensive AFCI coverage throughout homes.

According to the Electrical Safety Foundation International, AFCI devices prevent fires by detecting dangerous arc signatures and interrupting power before arcing ignites surrounding materials. These sophisticated devices distinguish dangerous arcs from normal arcing in switches and motor brushes, providing protection without nuisance tripping.

Installing and testing GFCI and AFCI devices correctly requires understanding their operation, proper wiring techniques, and testing procedures. Improper installation can create situations where protective devices fail to operate when needed despite appearing to function normally.

Grounding and Bonding Requirements

Proper grounding protects against electric shock by providing a low-resistance path for fault currents to flow safely to earth. Bonding connects metal components to ensure they’re at the same electrical potential, preventing dangerous voltage differences between metal parts.

Modern code requires grounding for all circuits and bonding of all metallic components that could become energized. This includes electrical boxes, conduit systems, water pipes, gas pipes, structural steel, and any other metal that might contact electrical circuits.

The grounding electrode system connects your electrical system to earth through ground rods, water pipes, or other approved electrodes. This system provides the reference point for your electrical system and safely dissipates fault currents and lightning strikes.

Grounding and bonding requirements have become progressively stricter as research reveals their importance in preventing electrocution and equipment damage. Homes built before current requirements may lack adequate grounding, creating hazards that aren’t visible until problems occur.

Working with professionals who specialize in professional electrical installation ensures grounding and bonding meets current code requirements through proper connection techniques, adequate conductor sizing, and compliant electrode systems. These critical safety systems require expertise and testing equipment that DIY installers typically lack.

Junction Boxes and Wiring Methods

Code strictly regulates how wires are connected and protected. All wire splices and connections must occur inside listed junction boxes with appropriate covers. This prevents accidental contact with live connections and contains any sparking or arcing within fireproof enclosures.

Junction boxes must remain accessible for future maintenance or modifications. Burying junction boxes behind finished walls or ceilings violates code because concealed connections create maintenance problems and fire hazards if issues develop.

Wiring methods vary based on installation location and exposure. Interior walls typically allow non-metallic sheathed cable (Romex), while some jurisdictions require conduit in certain locations. Outdoor installations, exposed indoor locations, and commercial applications have specific wiring method requirements.

Cable must be protected from physical damage through appropriate routing, stapling at code-specified intervals, and protection plates where cable passes through studs or joists. Improper cable routing creates damage risks that can cause short circuits and fires years after installation.

These seemingly minor details significantly impact safety and longevity. Professional electricians internalize these requirements through training and experience, consistently applying proper methods that DIY installers often overlook.

Special Requirements for Specific Areas

Different areas of your home face different electrical hazards and have correspondingly specific code requirements. Kitchens require multiple 20-amp circuits for countertop outlets, dedicated circuits for major appliances, and GFCI protection for specific locations.

Bathrooms need GFCI-protected outlets, properly rated exhaust fans vented to exterior, and lighting circuits separate from outlet circuits in some configurations. The combination of water and electricity demands extra precautions.

Garages require GFCI protection for outlets, proper height requirements for outlets and switches, and consideration for door opener circuits and potential EV charging installations.

Outdoor electrical installations face weather exposure requiring specialized boxes, covers, wire types, and protection methods. Circuits serving outdoor areas need GFCI protection and proper burial depth for underground wiring.

Each area has detailed requirements addressing specific hazards and use patterns. Professionals familiar with these requirements ensure compliant installations that serve your needs safely.

Permit Requirements and Inspections

Most electrical work beyond simple repairs requires permits to ensure compliance with code and safety standards. Permit requirements vary by jurisdiction, but typically include circuit additions, service upgrades, major appliance installations, and any work involving new wiring or panels.

Permits initiate an inspection process where municipal inspectors verify work meets code requirements. Inspections occur at specific project milestones—rough-in inspections before walls close, and final inspections after work completion.

Some homeowners view permits as unnecessary bureaucracy, but inspections serve critical safety functions. Inspectors identify code violations and safety hazards that might remain hidden for years before causing problems. Catching these issues during construction prevents much more expensive corrections later.

Insurance companies and mortgage lenders often require permitted electrical work. Non-permitted work can void homeowner’s insurance, prevent home sales, or require expensive remediation to obtain financing approval.

Professional electricians handle permit applications, coordinate inspections, and ensure work passes inspection without requiring corrections. Their experience with local codes and inspector expectations prevents delays and ensures compliant results.

The Costs of Non-Compliance

Code violations create multiple risks beyond immediate safety hazards. Homes with unpermitted or non-compliant electrical work may experience insurance claim denials if electrical issues cause fires or other damage. Insurance companies can legitimately deny claims when negligence or code violations contributed to losses.

Home sales often reveal electrical code violations during buyer inspections. Sellers must either correct violations or accept reduced offers accounting for necessary repairs. These unexpected costs frequently exceed what professional installation would have cost initially.

Local building departments can require expensive corrections when code violations are discovered, whether through complaints, permit inspections for other work, or sale-related inspections. Correction costs often exceed original installation costs, particularly when finished walls must be opened to access non-compliant work.

Most significantly, code violations create real safety hazards. Electrical fires kill hundreds and injure thousands annually, while electrocutions claim additional victims. Many of these tragedies result from code violations that proper installation would have prevented.

Why Professional Installation Is Essential

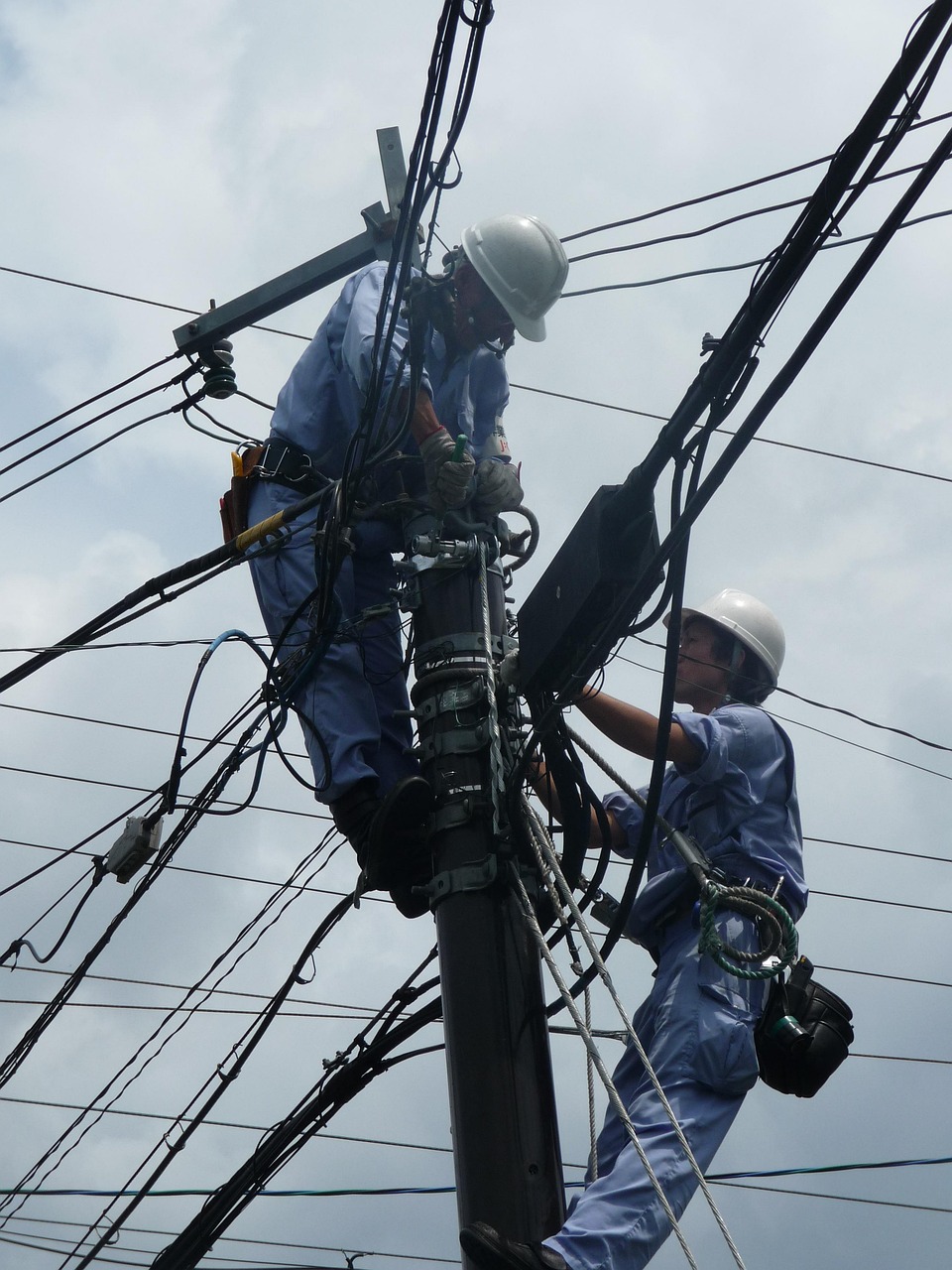

Electrical codes span hundreds of pages covering countless specific requirements and exceptions. Licensed electricians spend years learning these requirements through formal education, apprenticeship programs, and continuing education. This expertise simply cannot be replicated through DIY research.

Professional electricians also carry proper tools, testing equipment, and materials to ensure compliant installations. Proper installations require more than basic hand tools—electricians use specialized equipment for testing, terminating, and verifying proper operation.

Licensed electricians maintain insurance protecting homeowners from liability if accidents occur during work. They also provide warranties standing behind their work if issues develop. DIY installations offer no such protection.

Perhaps most importantly, professional electricians understand not just what code requires, but why those requirements exist. This deeper understanding helps them apply code intelligently to unique situations while maintaining safety and compliance.

Making the Right Choice

Electrical work directly impacts your family’s safety and your home’s value. While DIY electrical work might seem to save money initially, the risks—code violations, safety hazards, insurance complications, and potential home sale obstacles—far exceed any savings.

Investing in professional electrical installation ensures your work meets code requirements, passes inspections, and serves you safely for decades. Licensed electricians bring expertise, experience, and accountability that DIY approaches cannot match.

For all electrical projects beyond simple repairs, choose licensed professionals who understand code requirements and apply them correctly. Your home’s electrical system is too important to trust to anything less than professional installation from qualified electricians.